Electric Pumps

COA, COP series

Immersible pumps

COA, COP series

Immersible pumps

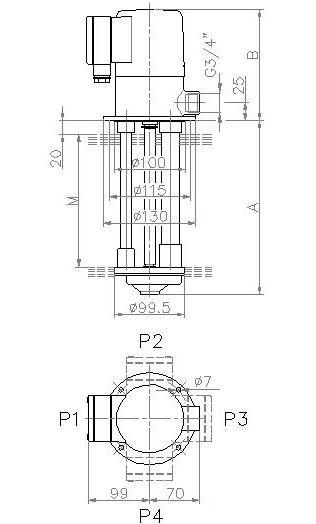

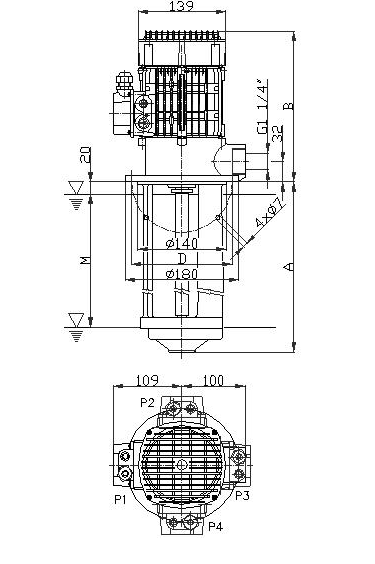

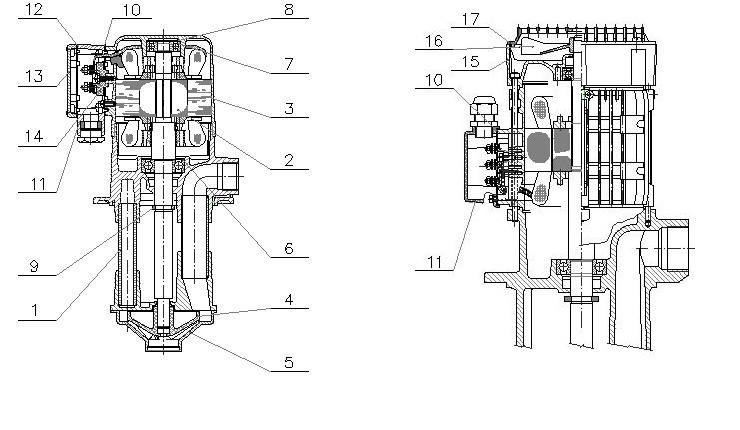

The electric pumps are equipped with a flange which enables their fitting directly on top of the tank, which contains the pumped liquid. The maximum and the minimum immersion level is shown on the dimensional drawing. The pumps must not be used for pumping of flammable or combustible liquids. The size of impurities in the pumped liquid should not exceed 0.5mm. Should larger impurities be found in the pumped liquid the pump suction opening should be equipped with a protective sieve. The standard paint finish the electric pumps are supplied with is S 2003 synthetic primer.

COP Pumps = „Plastic execution“

COA Pumps = „Aluminium execution“

There is a table with all executions and their materials at the end of this page (section „Used materials“)!

COP Pumps = „Plastic execution“

COA Pumps = „Aluminium execution“

There is a table with all executions and their materials at the end of this page (section „Used materials“)!

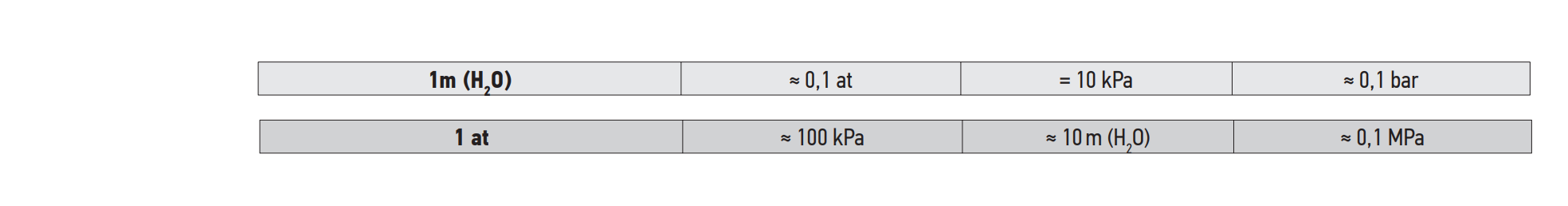

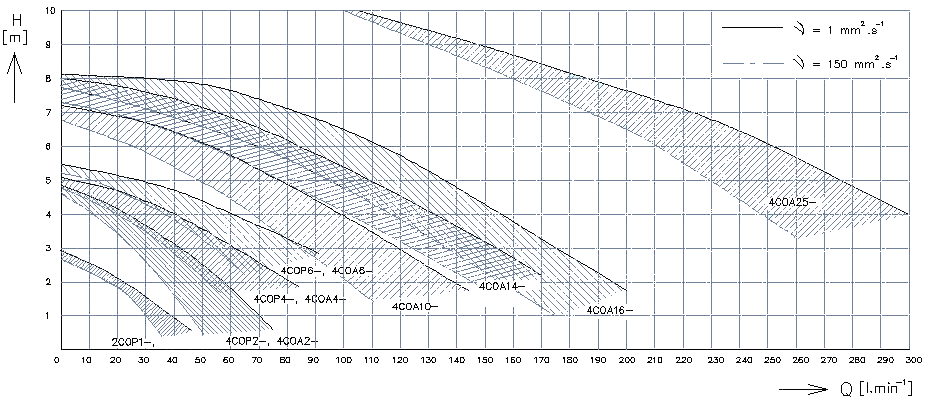

| HEAD | 2-4m |

|---|---|

| FLOW | 16-260l/min |

COA, COP Pumps - Technical Data

| Type | Head | Pressure | Flow | Power | Current | Assured current |

|---|---|---|---|---|---|---|

| m | kPa | l/min | kW | A (by 400V) | A (by 400V) | |

| 2COP1-; | 2 | 20 | 16 | 0,05 | 0,14 | 0,22 |

| 4COP2-; 4COA2- | 4 | 40 | 25 | 0,09 | 0,26 | 0,35 |

| 4COP4-; 4COA4- | 4 | 40 | 40 | 0,12 | 0,33 | 0,45 |

| 4COP6-; 4COA6- | 4 | 40 | 63 | 0,155 | 0,43 | 0,6 |

| 4COA10- | 4 | 40 | 100 | 0,36 | 0,71 | 0,84 |

| 4COA14- | 4 | 40 | 140 | 0,39 | 0,74 | 1,1 |

| 4COA16- | 4 | 40 | 160 | 0,505 | 1,1 | 1,6 |

| 4COA25- | 5 | 50 | 250 | 0,96 | 1,6 | 2,3 |